SENHO water cooled chillers feature compact design and high efficiency. With generously sized shell and tube condenser and for heat removal, they perform reliably & powerfully. Top components and fine processing skills ensure high quality and reliability of SENHO water cooled chillers.

Small footprint make SENHO water cooled chillers very suitable for limited space installation. With no heat discharged to the surrounding air, water cooled chillers can be installed in a room with poor ventilation conditions.

9.2KW to 2590KW cooling capacity is within the standard range of our water cooled chillers. Modular type design makes it easy to expand the capacity for larger scale cooling process.

We offer water cooled chiller solution for varies of applications and working conditions including:

● Scroll type, screw type or reciprocating type compressor.

● Complete stainless steel heat exchangers for dionized water, food process or medical use cooling.

● Acid corrosion resistance heat exchangers for processes like surface treatment.

● Sea water condenser for marine use.

SENHO provides not only a comprehensive range of water cooled chillers, but also professional customized cooling solutions for various industries and applications.

A properly selected water cooled chiller will have a longer service life and better performance. Please let us know more details about your applications.

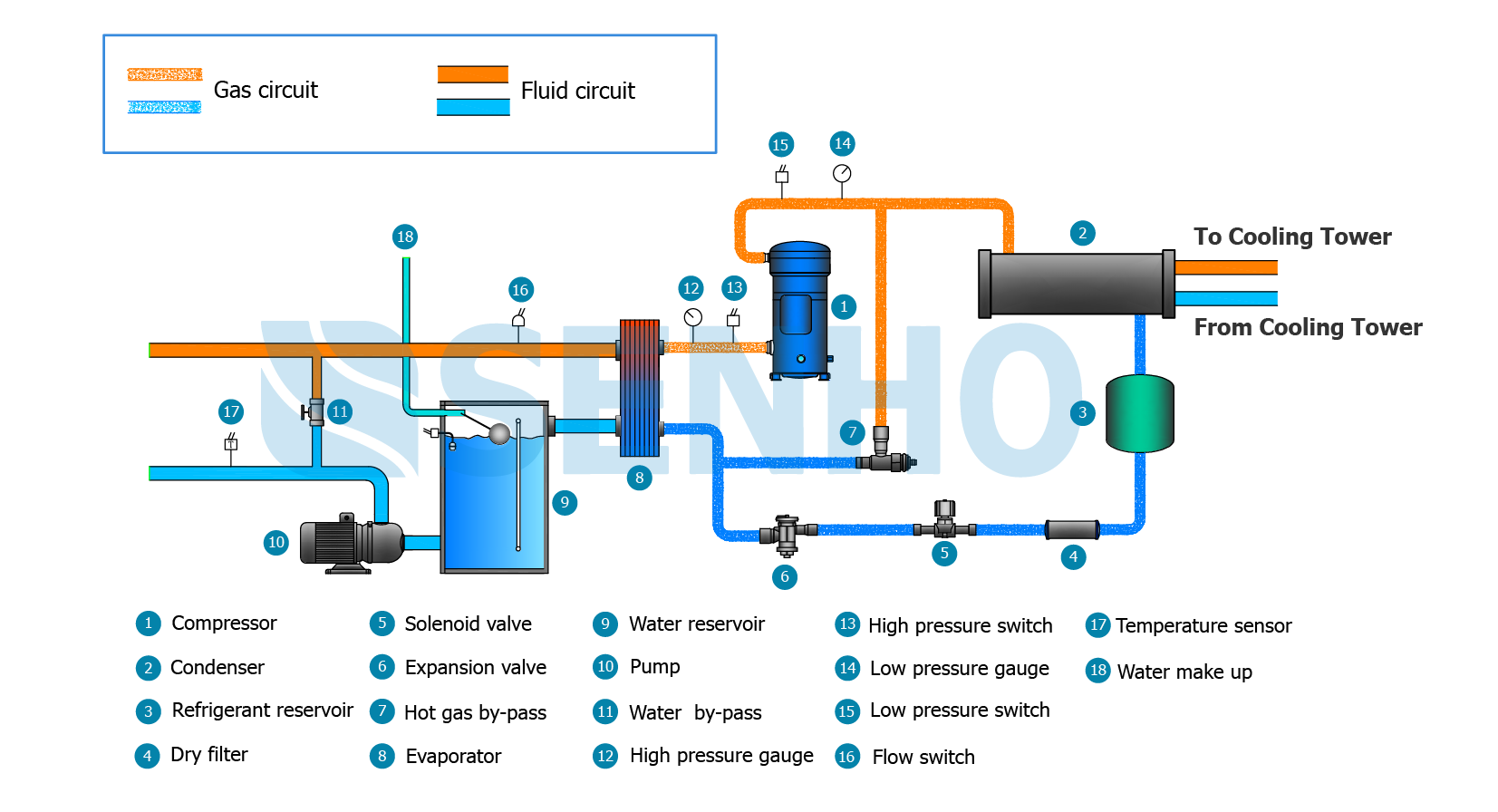

Working Principle of Water Cooled Chiller

Available Models for Water Cooled Chillers

▋Water-cooled Industrial Chillers << Click to view

· Cooling capacity range from 7.9KW to 242.4KW

· Danfoss or Copeland hermetic scroll compressor

· Built-in hydronic module(chilled water pump and chilled water tank)

▋Water-cooled Central Chillers << Click to view

· Cooling capacity range from 88KW to 2590KW

· Bitzer or Hanbell semi-hermetic screw compressor

· Siemens S7-200 Smart Series programmable logic controller

▋Water-cooled Low Temperature Chillers << Click to view

· Cooling capacity range from 1KW to 2590KW

· Cooling temperature range from -40℃ to 5℃

· Ethylene glycol, propylene glycol or brine can be selected as cooling medium